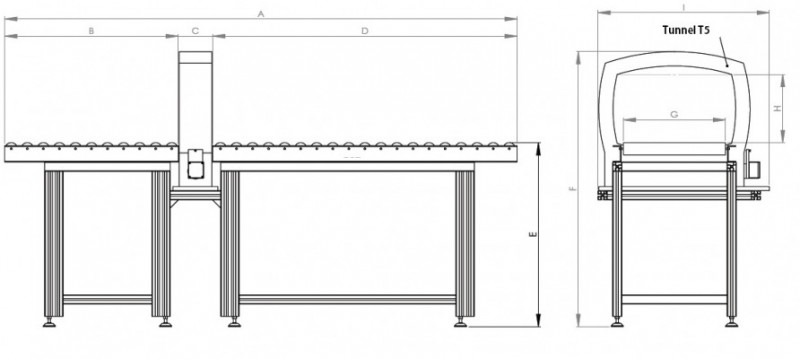

Tunnel demagnetizer with roller conveyor

-

- Heavy duty construction

- Long service life

- Effective

- According to VDE,CEE standards

-

- Heavy duty construction

- Long service life

- Effective

- According to VDE,CEE standards

- High performance resin encapsulated coil (black)

- Reinforced system

- Aluminium frame

- High quality rollers

- On/off switch with pilot light

- Thermal circuit breaker

- .Electrical box

A part to be demagnetised must be exposed to an alternating magnetic field which reduces H. In order to demagnetise these parts, either to comply with a specification (automotive standards, etc.) or to carry out machining (on a wire machine, for example), the part is passed through the tunnel at a slow and constant speed (approximately 0.2 m/sec). It is essential to take the workpiece out of the demagnetiser by 40 to 60 cm before switching it off.

Demagnetisation test possible. Ask your technical advisor.

Demagnetisation test possible. Ask your technical advisor.

-

Use :

- Demagnetization

-

Voltage :

- 230/400/480 VAC

-

Duty cycle :

- 25 à 100 %

- manual/motorised rollers

- Specific frame

- Starting box with workpiece position sensor

- Automatic machine for multiple demagnetizing passes

- Frequency down converter for demagnetizing difficult to demagnetize parts