Undertaking and Innovating : A history of Braillon tradition 1921 Jean-Marie Braillon and his friend Georges Bardin, graduated from the same school, found the company Bardin-Braillon. The company ensures the maintenance of machine motors and alternators in the factories of the valley. Its specialization in electrical winding will enable the evolution towards manufacturing of worldwide reputed electromagnetic products. The Swiss Zehnder files the patent for electromagnetic chuck using the alternating current. The two young partners, conscious of the benefit of the patent, decide to buy the licence to manufacture the chuck.       |

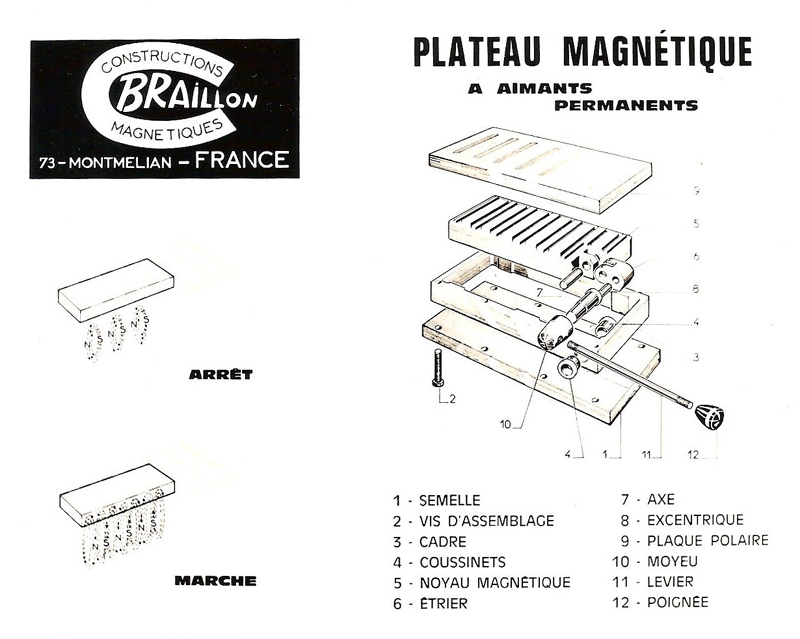

1925 After having improved the manufacturing process of the Suisse patent, the company Bardin-Braillon files on its turn the patent for the magnetic chuck working with alternating and direct current. 1930 Georges Bardin leaves Montmélian and returns to Bourgogne. Mr Jean-Marie Braillon runs alone the company with the name “Anciens établissements Bardin et Braillon” (“Former company Bardin and Braillon”). 1934 The period of diversification: the company takes over “Le fil Métallique Lyonnais” and manufactures consumer products like letter and paper clips, letter corners, pencil sharpeners as well as the knitting needles and crochets. 1935 Taking over of the company Sainy André situated in Paris (34, rue de Seine). Manufacturing of push-pins is transferred to Montmélian due to the existence of cold presses. 1934 - 1943 The name of the company remains « Anciens établissements Bardin et Braillon ». The company SFAIA moves its headquarters from Thonon to Chambery and permits to commercialize the products manufactured in Montmélian. This company becomes later « la Société française d’applications industrielles des aimants » (French company for industrial applications of magnets). 1943 The company becomes " Etablissements J. Braillon". 1949 Philibert, the son of Jean-Marie Braillon joins the family business after having graduated Ecole Centrale de Lyon. As his father 28 years before, he will develop the new magnetic chuck together with a friend met at the school. 1951 Patent for the magnetic chuck which will become the world famous product. 1963 Purchase of the Benetto patent on electropermanent system. Starting from this moment the Braillon company will develop the electropermanent magnetic chucks and lifting magnets. 1965 Patent for EPBJP magnetic chuck 1976 The company has 150 employees and 2 production sites : MONTMELIAN and the factory La Peysse in Barberaz, near Chambery. 80% of sales are realized in foreign markets : the USA, Japan, Mexico, Taiwan, Germany, Turkey, Sacandinavaian, United Kingdom... more than 72 destinations for the magnetic chucks and lifting magnets. The 60ies and 70ies These years stand out because the following new products, they will make Braillon Magnetics world renowned: BJP, ICA, PEP, Rotary Chucks BC and ERC and of course the famous magnetic lifter with Alnico permanent magnets. 1984 With the emergence of Neodymium, Philibert Braillon asks the design office to focus on new, small pitch chuck with neodymium magnets. 1989 Philibert Braillon decides to sell the company Braillon SA to the American group WALKER MAGNETICS. 1990 Development of the first magnetic platens for injection moulding machines. 1993 Relocation to the new facility : ALPESPACE : 5000 sq.m. on 2 hectares of land. 1994 New permanent lifting magnets type NND are introduced into the market : more than 3000 units per year will be manufactured up to 2000. 1998 Development of electropermanent miling chucks with neodymium magnets. 2000 Braillon Magnétique becomes Walker Braillon Magnetics. 2011 The company Braillon Magnetics is taken over By Mr. Hubert Burlat, the founder of the companies BMS ( Bridage magnétismes et systèmes) based in Levallois-Perret, and BURLAT-MAGNET-SYSTEME GmbH based in Germany. 2012 Redeployment of Braillon Magnetics internationally. 2013 Installation of a new, large capacity machining center : 2200 x 1500 mm. |

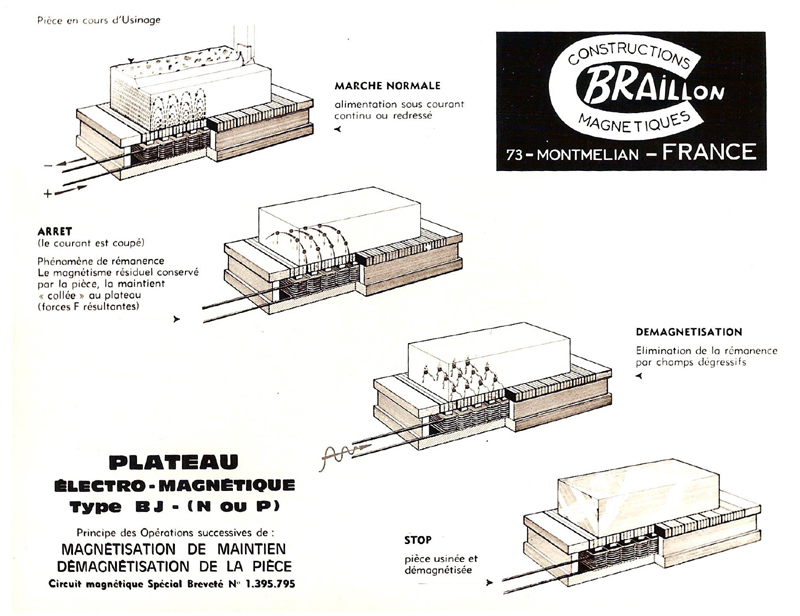

Magnetism since 1921