Our Technologies

|

Permanent Magnets

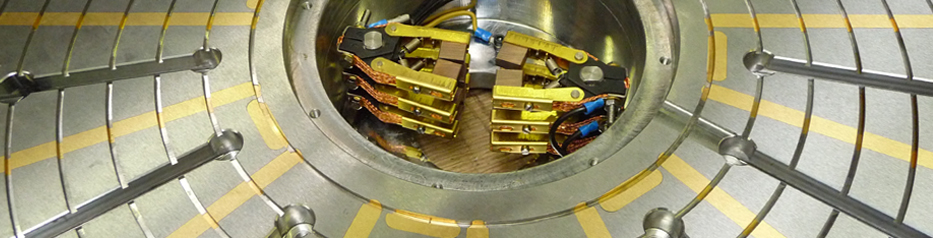

A permanent magnetic chuck is simply activated and deactivated mechanically. |

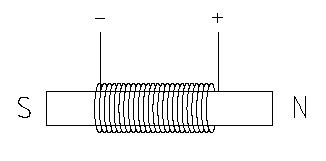

Electromagnets

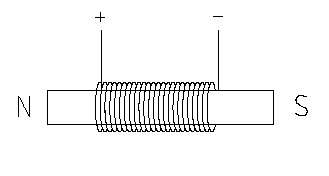

When applying a continuous electrical current to a steel conductor, a magnetic field is created : |

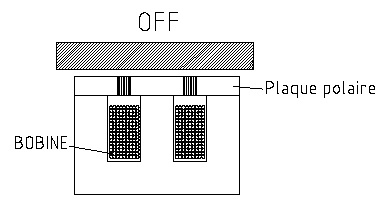

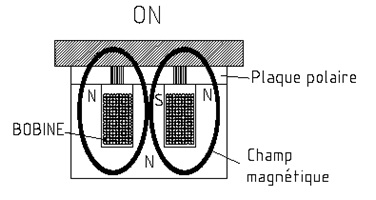

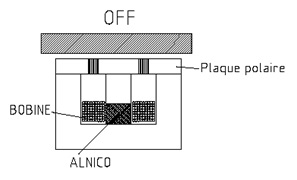

Electro-permanent

Full demagnetization system

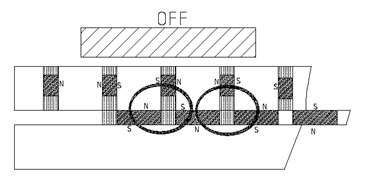

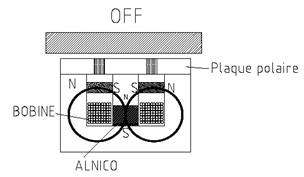

The ALNICO magnet is inactive.

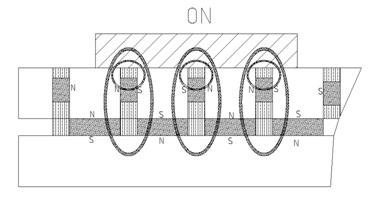

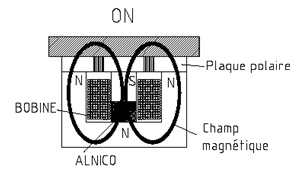

It is not at all magnetized :  By sending a continuous electrical pulse to the coil. The part is then magnetized and held firmly :

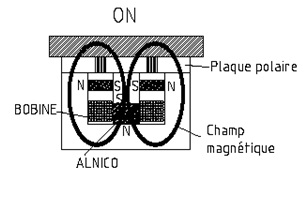

Compensated System The magnetic flux locks itself inside the chuck And the part is released and free :  By sending an electrical pulse to the coil. We change the magnetic direction of the ALNICO magnet. This allows the magnetic flux to go through the part itself. The part is then held. To release the part, we send an inverted electrical pulse To the coil that enables the polar direction to change :  |

| Matériaux, découvertes et principes fondamentaux de nos technologies actuelles | ||

| Eres | Discovery | |

| Magnets used for navigation Discovery of new continents |

- 1000 0 1000 |

• Natural magnetic rocks (Fe3O4) Discovered in Minor Asia in the town of MAGNESIE a rock named magnétite. • Discovery of Iron • Iron is magnetized with of the magnétite • Compass with floating needle |

| Navigation | 1200 | • First compasses |

| Study of electrostatics and magnetostatics | 1600 1800 |

• 1st scientific study on magnets conducted by GILBERT • 1st magnetic circuit (rock + steel) for experiences. • Electrostatic studies • Iron magnets • VOLTA invents the battery |

| Dynamic electricity |

1820 1850 |

• Relation between magnetism and electricity by OERSTED (the scientist that observed the deviation of the compass) • The laws of electromagnetism. AMPERE (the genius that in 1 month will establish these laws) • Motors and dynamos with magnets |

| Electrical Machines | 1900 | • Powerful Electro magnets • Dynamo machines • Industrialization of motors All of these are found in electrical meters, telephones, ignition magnetos … |

| Development of magnetic materials |

1930 1938 1941 1970 1983 |

• Mishima (Japan) isotopic Molded alloys 58%fe – 30% Ni – 12% al : ALNICO • England -Anisotropic molded alloys (Field treated- oriented magnets) 50%fe – 24%co - 14%Ni – 8% Al • Néel (France) Ferrite – Magnetic powder Industrialization by Philips (1955) • Japan : Rare earth magnetic powder Samarium Cobalt (SmCo) very expensive • Japan + USA – Rare earth magnetic powder (without cobalt) high powered magnets Néodyme+fer+bore+praseodymium (NdFeB) |

|

Three types of magnets are used today

|

||

|

ALNICO Iron – Cobalt – Nickel – Titanium – Aluminum |

FERRITE Iron oxide - Strontium carbonate - Binder |

NEODYMIUM Neodymium – Iron - Boron Metallurgy process : - Fusion of constituents - Grinding - Compression under field - Sintering at 1100° - Thermal treatment - Machining - Control – Magnetization Density : 7,3 Max temp use: 100° C Max induction : 13.000 G Max coercivity field : 12.000 Oe This Magnet discovered in the 80’s will revolutionize the magnet world, due to it’s extremely high magnetic performances. It’s ratio of induction (force) to volume is amazing. It’s resistance to corrosion is pretty weak so most applications will require a surface protection, a Nickel protection is applied to certain lifting magnets. These magnets are used to fabricate the last generation of permanent lifting magnets so that the magnetic force stays the same through time (high coercivity field) with the same lifting capacity with a ratio of force to volume can be divided by 3. For example, a lifting magnet of 400kg that weighs 54kg with ferrite magnets only weighs 10kg with neodymium magnets ! |

|

A few magnetic principals

|

|||||

The magnetic flux always goes from the north pole to the south pole The magnets with the same polarity are repelled by each other, and attract each other if they are opposite. Ferromagnetic parts are the ones that conduct magnetic flux the best. The greatest resistance for the magnetic flux is air. The magnetic flux lines must never cross each other. Every flux line is closed, they have no beginning or end. |

Knowing that the magnetic saturation of standard steel is at 16,000 Gauss, our job is to aim to get the max flux in the maximum surface to get as close as possible to 16,000 Gauss. We use several different terms when speaking of magnetic fields :

You can easily go from one format to another using the conversion principals in this chart. |

||||

| Gauss | Tesla | Amper per Meter | |

| 1G | 0,1 mT | 80 A/m | |

| 1 mG | 0,1 µT | 0,08 A/m | |

| 10 000 G | 1 T | 800 000 A/m | |

| 1 mG | 100 nT | 80 m A/m | |

| 10 mG | 1 µT | 0,8 A/m | |

| 12,5 mG | 1,25 µT | 1 A/m | |

| 1 Gauss = 1.000 milligauss (mG) 1 Tesla = 1.000 millitesla (mT) = 1.000.000 microtesla (µT) = 109 nanotesla (nT) 1 A/m = 1.000 milliamper/m (mA/m) |

|||