REF 11.14

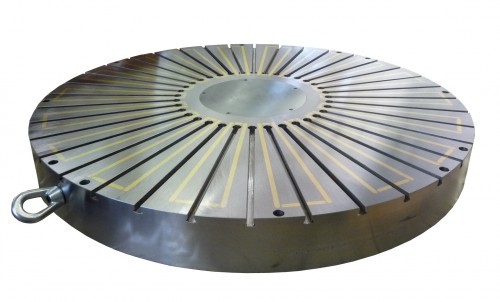

Electro-permanent Circular Magnetic Chuck type EPERC

-

- High holding power

- Heavy duty construction

-

- High holding power

- Heavy duty construction

. Electropermanent radial pole circular chuck with high holding force

. Space between the poles filled with brass

. For ring-shaped workpieces

. Suitable for grinding and turning operations

. Corresponding Control Unit and the Remote Control to be ordered separately:

See 50.03.BUP.230400/480 and 50.10.T10

Included with purchase:

- Electric connection at the rear of the chuck

- With slip ring assembly either integrated into the chuck or separate (to be fitted to the machine spindle)

. Space between the poles filled with brass

. For ring-shaped workpieces

. Suitable for grinding and turning operations

. Corresponding Control Unit and the Remote Control to be ordered separately:

See 50.03.BUP.230400/480 and 50.10.T10

Included with purchase:

- Electric connection at the rear of the chuck

- With slip ring assembly either integrated into the chuck or separate (to be fitted to the machine spindle)

-

Use :

- Grinding

- Turning

-

Nominal force :

- 140 N/cm²

-

Admissible wear of top plate :

- 8 mm

-

Voltage :

- 340 VDC

- Other sizes and voltages on request

- T-slots in each pole

- Through hole in the middle

- Customized raising pole shoes

- Fitting adaptors to:

. Morse cone 3 or 4

. Short taper flanges for:

A2 DIN 55026

Bayonet DIN 55027

Camlock DIN 55029

- T-slots in each pole

- Through hole in the middle

- Customized raising pole shoes

- Fitting adaptors to:

. Morse cone 3 or 4

. Short taper flanges for:

A2 DIN 55026

Bayonet DIN 55027

Camlock DIN 55029

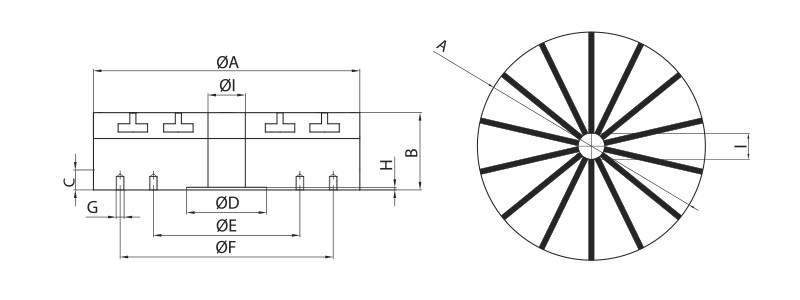

| Qty | Product | Weight in kg | A | B | C | D | E | F | G | H | I | J |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 11.14.150.6.340 | 9,0 | 150 | 90 | 14 | - | - | - | 3xM10 | 4 | 35 | 6 | |

| 11.14.200.8.340 | 18,0 | 200 | 90 | 14 | - | - | - | 4xM10 | 4 | 45 | 8 | |

| 11.14.250.8.340 | 29,0 | 250 | 90 | 16 | - | - | - | 4xM12 | 4 | 65 | 8 | |

| 11.14.300.12.340 | 42,0 | 300 | 90 | 16 | - | - | - | 4xM12 | 4 | 85 | 12 | |

| 11.14.400.12.340 | 76,0 | 400 | 90 | 16 | - | - | - | 6xM12 | 5 | 100 | 12 | |

| 11.14.500.16.340 | 120,0 | 500 | 90 | 16 | - | - | - | 6xM12 | 5 | 150 | 16 | |

| 11.14.600.16.340 | 195,0 | 600 | 100 | 18 | - | - | - | 6xM16 | 5 | 180 | 16 | |

| 11.14.700.16.340 | 265,0 | 700 | 100 | 18 | - | - | - | 6xM16 | 5 | 200 | 16 | |

| 11.14.800.24.340 | 365,0 | 800 | 100 | 18 | - | - | - | 6xM16 | 5 | 200 | 24 | |

| 11.14.1000.24.340 | 550,0 | 1000 | 100 | 18 | - | - | - | 8xM16 | 5 | 250 | 24 |

indication_tableau_dessus

indication_tableau_dessous